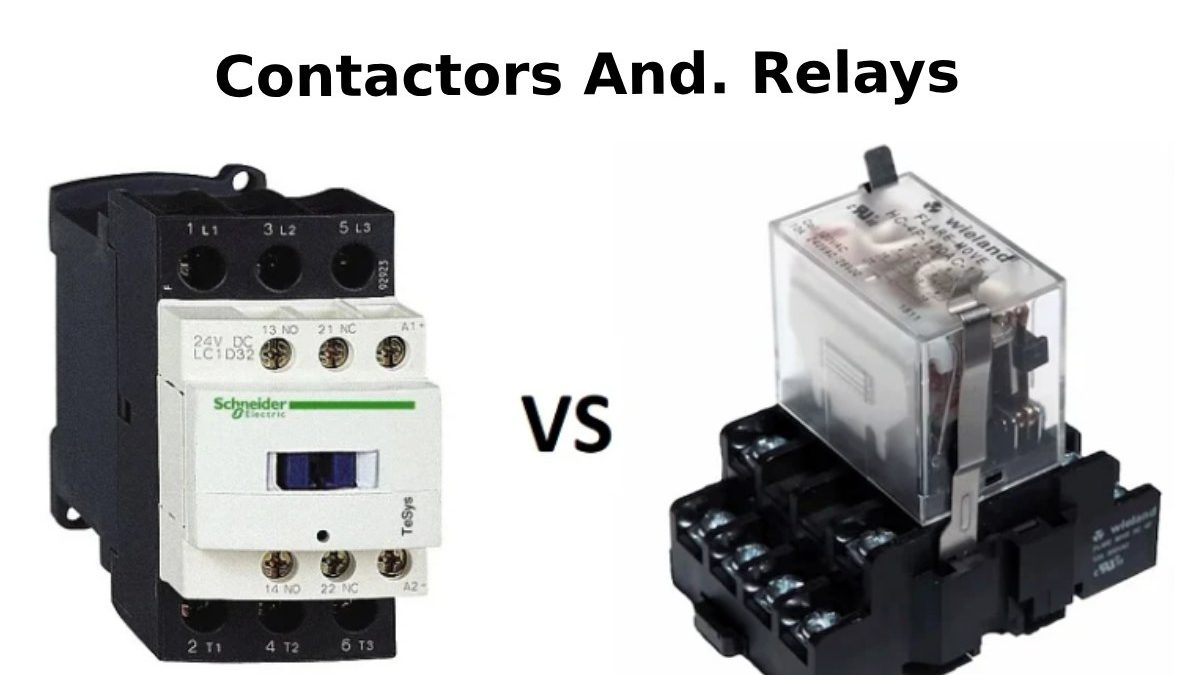

Contactors and relays are vital components in electrical control systems, each serving distinct purposes. Understanding their differences is pivotal for selecting the suitable component for a specific application.

While both contactors and relays are electrically operated switches, contactors are designed to handle significantly higher electrical currents, making them suitable for controlling motors, compressors, and other high-power loads. In contrast, relays are typically used for lower-power applications and control circuits.

Table of Contents

Understanding Contactors

A contactor is an electrically managed switch used to control high-power electrical circuits. It consists of a coil, a movable contact arm, and stationary contacts. When the coil is animate, the contact arm moves to establish a connection between the stationary contacts, allowing current to flow through the main circuit.

Contactors are primarily used for controlling motors, compressors, lighting circuits, and other high-power loads. They are designed to handle heavy currents and frequent switching operations.

Understanding Relays

A relay is an electrically worked switch that controls one or more electrical circuits using a low-power control signal. Like contactors, relays consist of a coil, but they are typically smaller and designed for lower current handling. Relays can be electromechanical or solid-state.

Relays are commonly used in control circuits, automation systems, and electronic devices to isolate circuits, protect components, and perform switching functions.

Contactors vs. Relays: Key Differences

The primary difference between contactors and relays lies in their load capacity. Contactors are designed to handle significantly higher currents and power levels compared to relays.

| Feature | Contactors | Relays |

| Load Capacity | High | Low to medium |

| Contact Ratings | High current, voltage | Lower current, voltage |

| Coil Power | Higher | Lower |

| Physical Size | Larger | Smaller |

| Typical Applications | Motors, compressors, lighting | Control circuits, automation |

Choosing The Right Component

Selecting the appropriate component depends on the specific requirements of the application. Consider the following factors:

- Load type

Determine the type of load (resistive, inductive, capacitive) and its power rating.

- Frequency of operation

Consider how often the component will be switched on and off.

- Environment

Evaluate the operating conditions, such as temperature, humidity, and vibration.

For high-power loads and frequent switching, a contactor is the preferred choice. A relay is suitable for low-power control circuits and less demanding applications.

Real-World Applications Of Contactors And Relays

To further illustrate the differences between contactors and relays, let’s explore some real-world applications:

- Contactors:

- Motor starters for industrial machinery

- Compressor sway in refrigeration and air conditioning systems

- Lighting control systems for large commercial buildings

- Relays:

- Automotive electrical systems

- Electronic control circuits

- Telecommunication equipment

- Automotive relays (horn, windshield wipers, etc.)

By understanding these applications, you can gain a better appreciation for the roles of contactors and relays in various industries.

Contactor And Relay Maintenance And Safety

Proper maintenance is crucial for ensuring the longevity and reliability of both contactors and relays. Regular inspection, cleaning, and lubrication can prevent premature failure and potential safety hazards.

- Contactors:

- Inspect contacts for wear, pitting, or arcing.

- Clean contacts with a soft brush or compressed air.

- Lubricate moving parts according to manufacturer’s recommendations.

- Check coil resistance and insulation.

- Relays:

- Inspect contacts for wear, pitting, or oxidation.

- Clean contacts with a soft brush or compressed air.

- Check coil resistance and insulation.

- Replace worn or damaged components.

Safety should always be a top priority when working with electrical components. Follow recommended safety procedures and wear appropriate personal protective equipment (PPE).

Contactors And Relays In Industrial Applications

Contactors and relays play vital roles in various industrial applications. Some common examples include:

- Motor control centers (MCCs)

Contactors are used to control large electric motors in industrial machinery.

- PLC systems

Relays are often used as output devices to control various electrical components.

- Power distribution systems

Contactors and relays are employed for switching and protection purposes.

- HVAC systems

Contactors control compressors and fans, while relays handle control circuits.

Understanding the specific requirements of industrial applications is essential for selecting the right component and ensuring optimal system performance.

Emerging Technologies: Solid-State Relays And Contactors

While electromechanical relays and contactors have been the industry standard for decades, advancements in semiconductor technology have led to the development of solid-state alternatives.

- Solid-state relays (SSRs)

Offer faster switching speeds, higher reliability, and longer lifespans compared to electromechanical relays. They are suitable for applications requiring precise control and high-frequency switching.

- Solid-state contactors (SSCs)

Provide similar benefits as SSRs but with higher current handling capabilities. They are gaining popularity in industrial applications where high performance and durability are essential.

Understanding the capabilities and limitations of solid-state components is crucial for staying up-to-date with the latest technologies in electrical control systems.

Conclusion

Understanding the differences between contactors and relays is essential for making informed decisions in electrical system design. By considering the load requirements, operating conditions, and desired functionality, you can select the appropriate component to ensure optimal system performance and reliability.

Looking To Learn More About Specific Contactors, Relays, Or Solid-State Options For Your Project?

Consider visiting the Schneider Electric website for a vast selection of electrical control components and resources. Their website offers detailed product information, application guides, and technical support to help you make informed decisions for your electrical control system needs.